Here everyone,

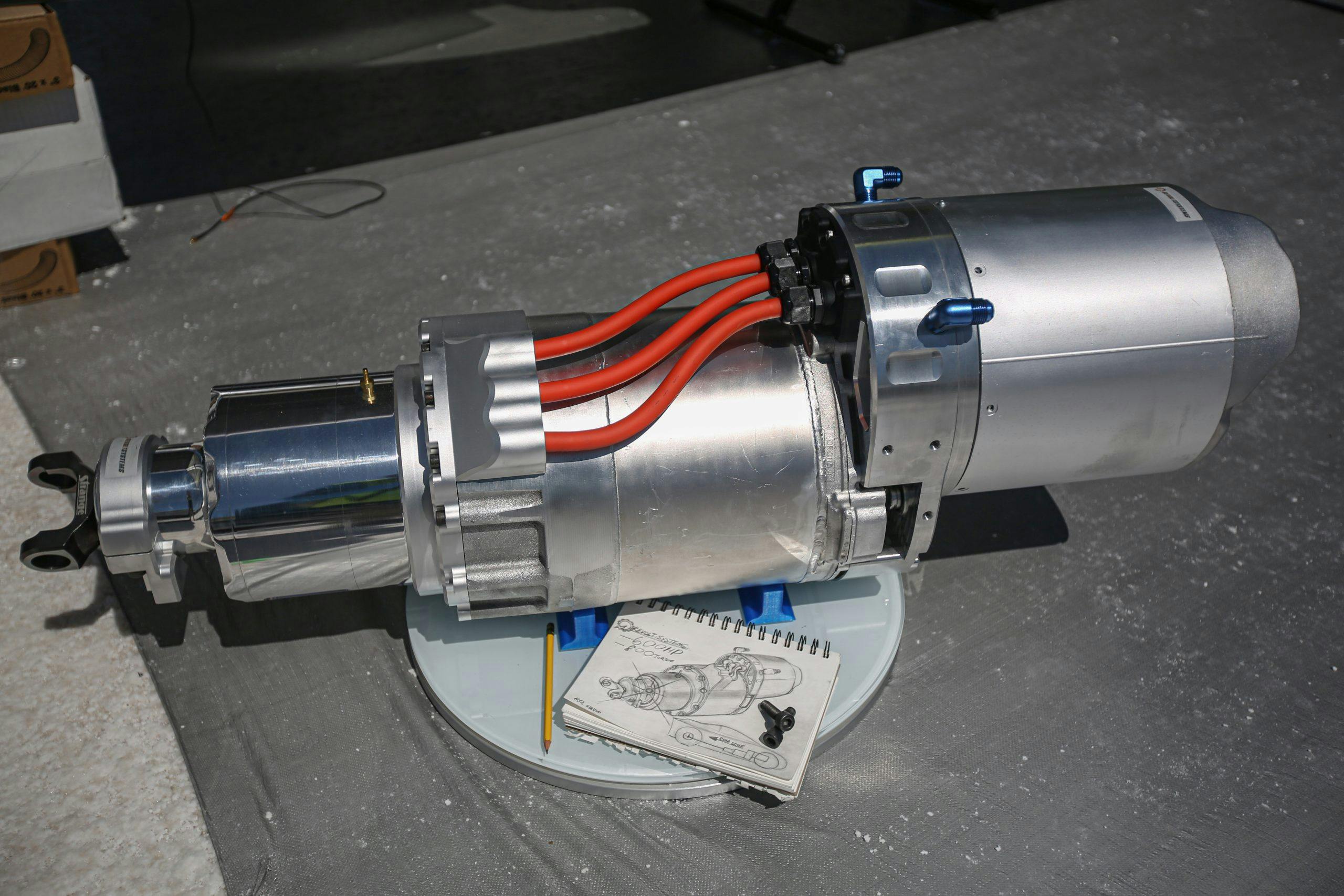

Thought I'd give you a project update as to what I've been working on ever since AEM bought my Mustang GT Tesla conversion. I decided to make an all wheel drive electric Ford Focus but got lost in Covid hell. So in the mean time I designed and built a new Tesla motor conversion for putting in old Mustangs and Camaro's that does not mean cutting up a classic car. So I developed a split Tesla motor with pressurized oiling, ability to run forward or reverse continuously and direct connect u joints or other types of power take off options. Here's a few picks. I have on the test bench right now playing with it. RPM red line should be about 5700 RPMs as with most V8 cars of yesteryear or yesterday. The motor and inverter are separate units now. Anyway enjoy a few pics. I'll now be hunting the donor car for the project. I'd really like a 1968 Plymouth Barracuda for this.

![122453 122453]()

![122454 122454]()

![122455 122455]()

Thought I'd give you a project update as to what I've been working on ever since AEM bought my Mustang GT Tesla conversion. I decided to make an all wheel drive electric Ford Focus but got lost in Covid hell. So in the mean time I designed and built a new Tesla motor conversion for putting in old Mustangs and Camaro's that does not mean cutting up a classic car. So I developed a split Tesla motor with pressurized oiling, ability to run forward or reverse continuously and direct connect u joints or other types of power take off options. Here's a few picks. I have on the test bench right now playing with it. RPM red line should be about 5700 RPMs as with most V8 cars of yesteryear or yesterday. The motor and inverter are separate units now. Anyway enjoy a few pics. I'll now be hunting the donor car for the project. I'd really like a 1968 Plymouth Barracuda for this.